15kV RMU Test Tooling product introduction:

The test tooling can provide lead wires for the high-voltage side of RMU factory testing or on-site acceptance of distribution equipment. It has good insulation performance, extremely low partial discharge, easy installation and disassembly, and high efficiency.

Implementation standards: IEC60502.4, GB/T12706.4

15kV RMU Test Tooling product features:

Silicone material with excellent electrical properties

The pre-mold is formed in one piece and the partial discharge is extremely small.

Can be used repeatedly, easy to install and disassemble

Electrical performance parameters of 15kV RMU Test Tooling:

NKS-15CS-01 | Items | Parameter |

| Technical Parameters | System Voltage | 15kV |

Rated current | 630A |

Frequency withstand voltage(AC) | 42kV/5min |

Partial Discharge | 15kV<5pC |

Impulse voltage | 95kV |

15kV RMU test tooling application:

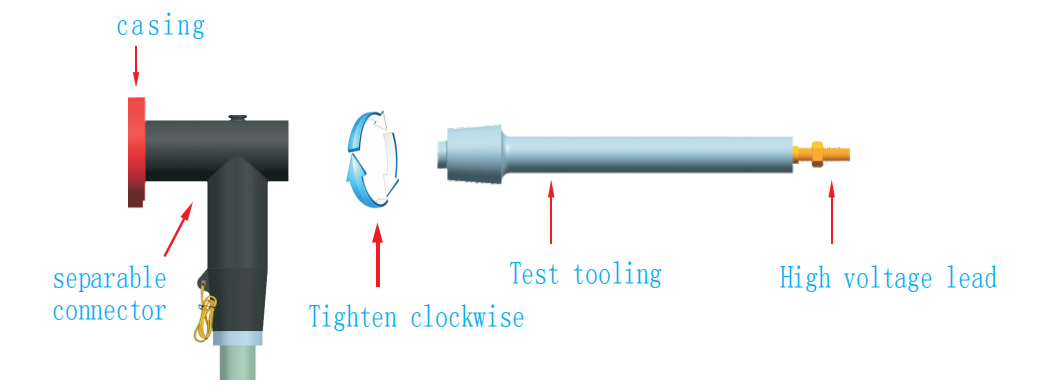

1. Use clean paper to clean the test tooling and casing. Wait until the cleaning agent has completely evaporated, and then apply silicone grease evenly.

2. Screw the test tooling into the tail of the connector body and rotate it clockwise to 30N/m until it is tightened in place. When disassembling, just rotate it counterclockwise.

3. Lock the high-voltage lead with the end conductor of the test tool.

4. Conduct the test after the grounding wires of each part are reliably grounded.