Low voltage heat shrink tubing product introduction:

Low-voltage heat shrinkable tubes are made of cross-linked environmentally friendly polyolefin heat shrinkable materials after irradiation expansion. They can provide high insulation strength and electrical resistance and are suitable for cable connections, cable terminations, busbar copper bars, and electrical equipment. Anti-corrosion and insulation protection.

Shrink ratio: 2:1 3:1; shrinkage temperature: 85℃~125℃; working temperature: -55℃~125℃

Low voltage heat shrink tubing product features:

High mechanical strength, suitable for a variety of power cables

Strong UV resistance and strong weather resistance

Has excellent insulation properties, corona resistance and tracking resistance

Simple design and reasonable structure

Electrical performance parameters of Low voltage heat shrink tubing:

Test Items | Test Methods | Test Requirements |

| Tensile Strength | ASTM D638 | ≥10Mpa |

| Ultimate elongation | ASTM D638 | ≥300% |

| Tensile Strength after Aging | ASTM D638 | ≥8Mpa |

| Ultimate elongation after aging | ASTM D638 | ≥250% |

| Longitudinal shrinkage | ASTM D2671 | ±5% |

| Dielectric constant | ASTM D2671 | ≥18Ω.cm |

| voltage breakdown strength | ASTM D149 | ≥25kv/mm |

| Volume resistivity | ASTM D257 | >1014Ω.cm |

| density | ASTM D792 | 1.22g/cm² |

| Flame retardancy | UL 224 | VW-1 |

| complete shrinkage temperature | ASTM D792 | 130±5℃ |

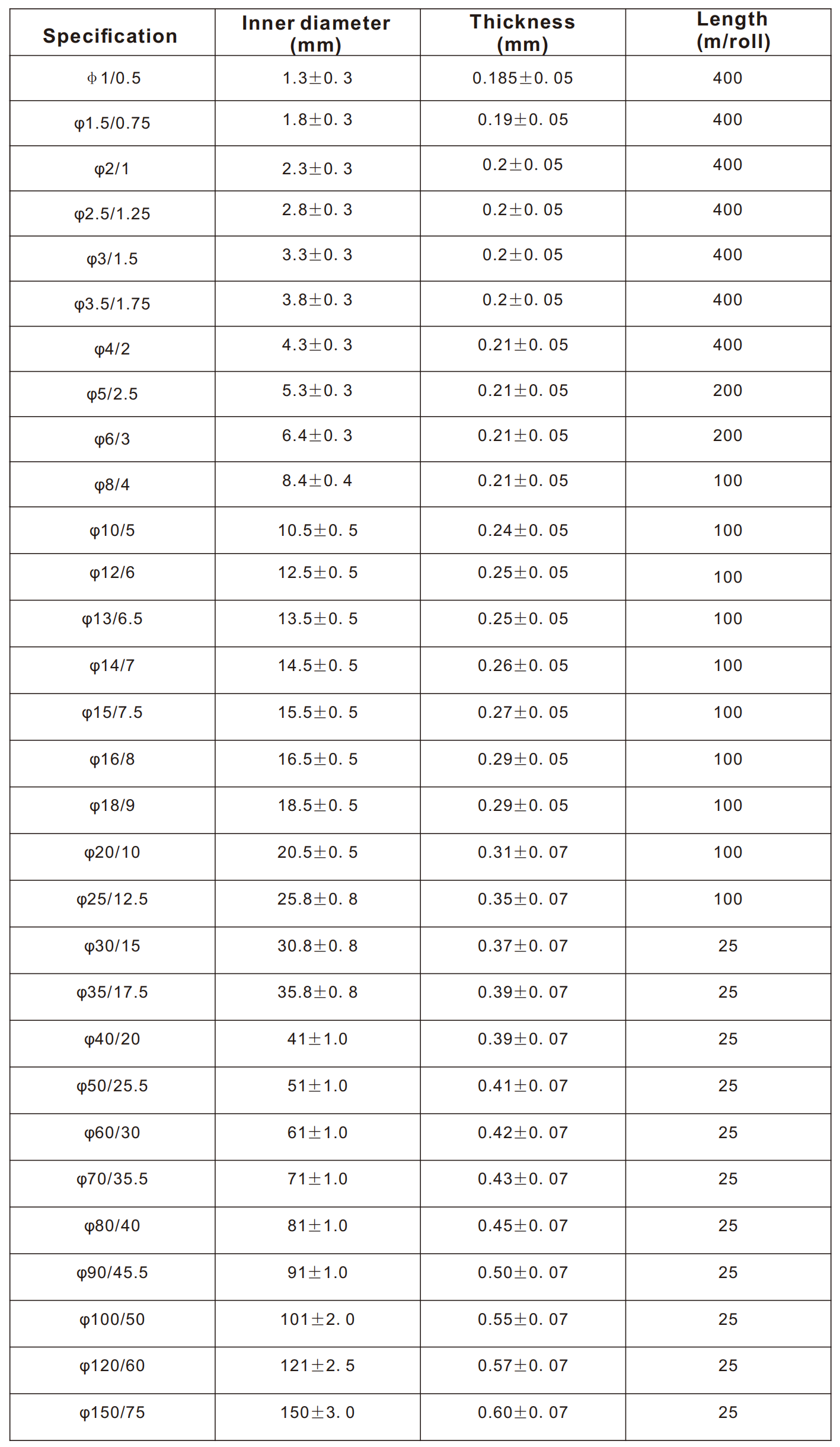

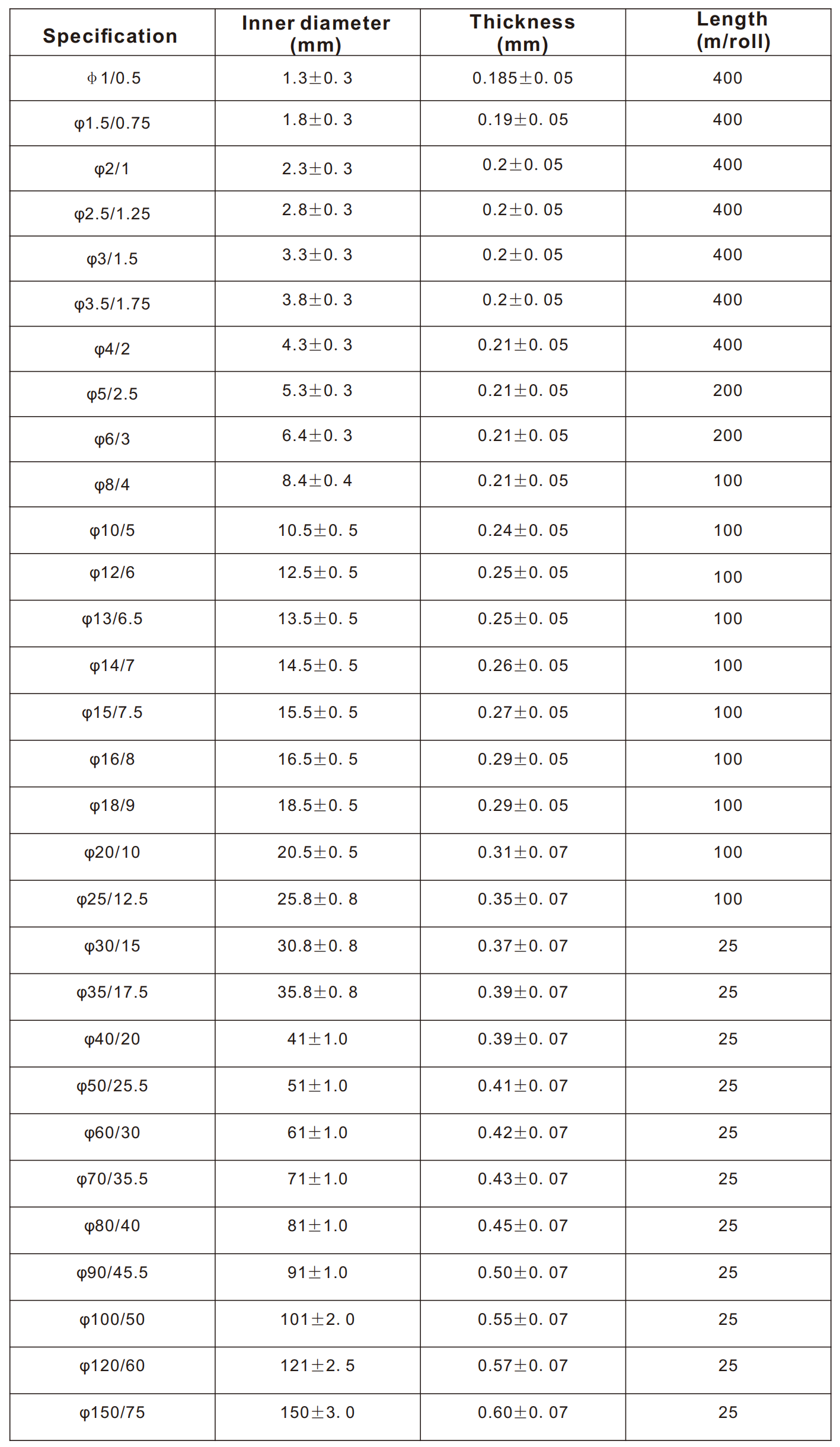

Selection table for Low voltage heat shrink tubing: